IASbaba's Daily Current Affairs Analysis, IASbaba's Daily Current Affairs July 2015, National, Science and Technology, UPSC

Archives

IASbaba’s Daily Current Affairs- 30th July, 2015

NATIONAL

Redesigning of Make in India

- To some, Make in India intends to foster innovation and build the economy by

attracting foreign investment to develop infrastructure in the manufacturing sector.

attracting foreign investment to develop infrastructure in the manufacturing sector. - To others, it focuses on domestically manufacturing products innovated by foreign firms. However, unless R&D is strengthened and the manufacturing ecosystem for homegrown entrepreneurs is developed, Make in India will not help the nation emerge as an innovation hub.

What the government is missing in formulating Make in India is design thinking?

- Make in India lacks systemic thinking, and does not have a human-centred approach, which are key tenets of design thinking.

- A systemic problem-solving process that can visualize or shape tools, society, policies, products, businesses and environment by driving human-centred and context-sensitive innovations.

- The programme also lacks granularity in terms of details and foresightedness towards building an innovation-driven nation.

What are the flaws in Make in India Design?

- First, due to a lack of systems thinking, Make in India will not lead to the creation of a sustainable economy.

- Second, due to a lack of empathy for domestic manufacturers and entrepreneurs, Make in India by itself will not foster domestic innovation.

- Third, Make in India does not encourage inclusive growth.

- Fourth, Make in India focuses on the economy, but misses on the socio-cultural and behavioral aspects of encouraging productivity.

What changes can Design thinking bring out?

- Design thinking can bring about societal change, especially when injected into the education system from kindergarten all the way to training of administrative officers and civil servants.

- Design thinking can be applied to visualizing new policies as well as re-framing existing policies, to make them human-centric, cohesive and to include multiple stakeholder needs and views, thus increasing their adaptability and efficiency in implementation.

- Sadly, in India, the most common notion of design is still only linked with aesthetics.

IAS BABA’s View

- A design thinking approach is essential to nurturing a culture of innovation.

- For Make in India to focus on inclusive growth through innovation, it must be clubbed with “Made in India”.

- It must focus on building a robust ecosystem and leading a cultural change that drives innovation encouraging entrepreneurs and intrapreneurs.

- By involving multi-stakeholder views and an iterative thinking cycle at the time of envisioning policy, granular details towards building up high quality R&D units and manufacturing to build an innovation ecosystem can be detailed out.

- Only then can Make in India bring about societal change, creating a new breed of thinkers and innovators who take pride in building high-quality products that are trusted for quality and that bear the imprint “conceived and manufactured in India”.

Connecting the Dots:

- Explain why Indian manufacturing sector needs to undertake more indigenous research and development to alien manufacturing with the principles of sustainable development?

- What explains India’s lackluster participation in Global production network for “Make in India”?

Sowing the seeds of a disaster: Compensatory Afforestation Fund Bill, 2015 (CAF Bill)

- There is cause for apprehension in the form of the Compensatory

Afforestation Fund Bill, 2015 (CAF Bill), which was introduced in the Lok Sabha.

Afforestation Fund Bill, 2015 (CAF Bill), which was introduced in the Lok Sabha. - The Compensatory Afforestation Fund Bill in its present form could squander away staggering amounts on meaningless afforestation. It must be recast to protect India’s forests

What is the Compensatory Afforestation Fund Bill?

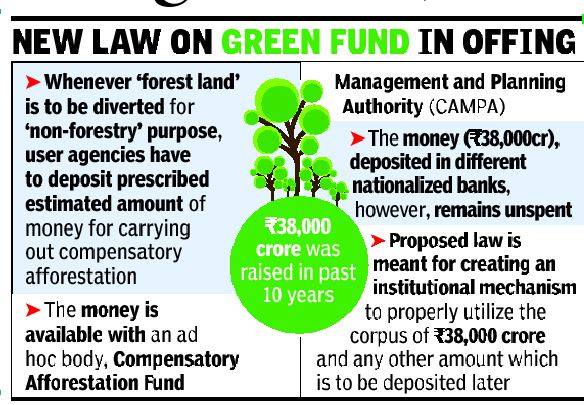

- Compensatory afforestation is defined as afforestation done in lieu of the diversion of forest land for non-forest use under the Forests (Conservation) Act, 1980.

- Creation of Compensatory Afforestation Funds: The Bill seeks to establish a permanent National Compensatory Afforestation Fund under the public account of India. It also allows states to establish State Compensatory Afforestation Funds.

- The National Fund will be under the central government, and managed by a National Compensatory Afforestation Fund Management and Planning Authority (CAMPA). The central government will appoint a State CAMPA in each state. The State CAMPA will be responsible for the management of the State Fund.

What are the special features of the Proposed Law?

- Creation of appropriate institutional mechanism, both at the Centre and the states” to utilize these funds for afforestation, and other purposes that would mitigate the effects of diversion of forest land.

- This “institutional mechanism” will replace the Compensatory Afforestation Management and Planning Authority (CAMPA) that currently exists but only in an “ad-hoc” manner.

- “The proposed legislation also seeks to provide safety, security and, transparencies in utilization of these amounts, which currently are being kept in nationalised banks and are being managed by an ad-hoc body.

How the compensatory afforestation approach ends up not just being a ‘greenwash’, but an ecological disaster as well? *(CASE STUDY + Example)*

- From 1980 to 2005, the Kudremukh Iron Ore Company Limited (KIOCL) strip-mined hill slopes clothed in virgin rainforests in the heart of Karnataka’s Kudremukh National Park.

- To ‘compensate’ for the loss of natural habitat, KIOCL went on a massive compensatory afforestation spree, planting millions of trees.

- The problem with this was twofold

- The trees were non-native species with zero biodiversity value;

- And they were planted on adjoining areas of natural grassland, which are an extremely important component of the Bhadra River’s watershed.

- Thus, apart from the forested hill slopes and the valley that were destroyed by mining activities, a third natural habitat, in the form of ecologically important grasslands, was destroyed through mindless tree planting.

- To add insult to injury, governments and project proponents alike proclaim such travesties as achievements towards a ‘Green India’.

IAS BABA’s View

- We are at a critical moment in India’s fight to achieve ecological security while ensuring economic and social progress.

- If recast on the basis of sound science, the CAF Bill 2015 will form the basis of a far-sighted and genuinely beneficial strategy to protect India’s forests.

- However, given the way it is crafted presently, it will allow Rs. 35,000 crore to be squandered away on corruption-ridden ‘afforestation’ projects involving digging pits, buying polythene bags for raising saplings, and planting trees that can never become forests.

Connecting the Dots:

- Write a note on National Compensatory Afforestation Fund (CAF)

- Discuss the key features of the Compensatory Afforestation Fund Bill 2015.

SCIENCE & TECHNOLOGY

After Nuclear-plants, Russia targets irradiation network

- In a step towards furthering the atomic cooperation with India, Russian state-owned nuclear firm Rosatom State Corp has picked up a 51 % stake in Tamil Nadu-based Gamma Tech India Private Ltd. to jointly implement a project that aims to set up a network of radiation sterilisation centres across India.

- The centres will be constructed in Tamil Nadu, Kerala, Karnataka, Andhra Pradesh and Maharashtra and the first pilot centre is planned to be established in Tamil Nadu.

- This is the first such major intervention by a foreign government nuclear utility in India, one of the largest food producers in the world with about 600 million tonnes of food products generated every year.

- The approval by the Indian nuclear regulator, the Atomic Energy Regulatory Board of India (AERB) for the irradiation equipment design and the construction of the first irradiation centre has already been obtained.

The centres to be developed by Rosatom will offer –

- sterilisation of medical products (by ionizing radiation) such as latex gloves

- decontamination of fruit, berries and other products exported from India to developed countries

Background:

What is Radiation sterilisation?

- Radiation sterilisation is a physical process of irradiation of medical products by ionizing radiation. Products are subjected to irradiation in specialised radiation technology facilities where gamma-rays (gamma-rays of Co-60 or Cs-137 isotopes) or electron accelerators are used.

How is it done?

- When electrons go through the material substance, most of their energy is spent on ionization, which results in destruction of micro-organisms and a reduction in the number of pathogenic bacteria and viruses.

- The process of radiation sterilisation is the final stage of production of single-use medical products. These technologies can be used in agriculture, as well as for municipal solid waste sterilisation and in the petrochemical industry. Over 42 countries in the world including the US, the UK, Canada and France have given clearance for radiation processing of food.

Radiation Technology in India:

- The Government of India has permitted the use of radiation technology in preservation of food items such as potato, onion, rice semolina, wheat flour, mango, raisins, dried dates, ginger, garlic, shallots (small onions) as well as meat and meat products including chicken.

- The Mumbai-based Bhabha Atomic Research Centre has done extensive research and development work on preservation of food by radiation and has been involved in setting up the first demonstration plant for radiation processing of onions and potatoes at Lasalgaon in Nasik, Maharashtra. The same plant is also proposed to be used for low dose radiation processing of other foods with alterations in throughput and source utilisation efficiency.

More about Atomic Energy Regulatory Board (AERB):

- Atomic Energy Regulatory Board was constituted on November 15, 1983 by the President of India by exercising the powers conferred by the Atomic Energy Act to carry out certain regulatory and safety functions under the Act.

- The regulatory authority of AERB is derived from the rules and notifications promulgated under the Atomic Energy Act, 1962 and the Environmental (Protection) Act, 1986. The headquarters is in Mumbai.

- The Mission of the AERB is to ensure the use of ionising radiation and nuclear energy in India does not cause undue risk to the health of people and the environment.

Courtesy- http://www.aerb.gov.in/