IASbaba's Daily Current Affairs Analysis, IASbaba's Daily Current Affairs Jan 2017, UPSC, Urbanisation

IASbaba’s Daily Current Affairs – 18th January 2017

Archives

URBANISATION

TOPIC: General Studies 1

- Urbanization, their problems and their remedies

Municipal waste management- Waste to energy plants

To manage solid waste or garbage in cities, there are three steps to it

- Segregation of biodegradable or wet waste from dry waste at source.

- Once segregation is achieved, municipal governments can use wet waste to produce compost and biogas in biomethanation plants.

- The dry waste, after removing recyclable elements, should go to waste-to-energy plants.

These steps will reduce the volume of waste that remains to be sent to landfills.

Waste to energy plants

- From the municipal waste, it is possible to generate energy in form of electricity and/or heat from the primary treatment of waste. It is done through Waste-to-energy process.

- A number of waste-to-energy plants are coming up in urban India which use incineration, Refuse Derived Fuel (RDF)-based combustion or conversion technologies such as pyrolysis and gasification.

Incineration

- A waste to energy plant based on incineration of unsegregated municipal solid waste in Delhi processes almost 2,000 tonnes of unsegregated municipal solid waste every day to feed into its boilers to produce 16 MW of electricity.

- These plants rely on mass burning of municipal solid waste, which involves complete combustion of miscellaneous waste materials into ash. However it is a huge challenge to determine what is municipal solid waste.

- The gases produced from such combustion may contain dioxins and furans, which are toxic and can be lethal.

- Thus, these plants need to have emission control filters of a very high standard to check the release of harmful gases into the atmosphere. It even came under fire initially as it did not comply with emission requirements but now it has received clearance from NGT.

- Another waste to energy plant in Delhi based on controlled combustion, produces RDF from segregated dry waste. RDF is fuel produced from various types of wastes such as Municipal Solid wastes (MSW), industrial wastes or commercial wastes. RDF consists largely of combustible components of such wastes, as non recyclable plastics, paper cardboard, Labels and other corrugated materials.

- This RDF is used in the same onsite boilers to generate electricity, performing at EU standards of emissions.

- The plant receives 1,300 tonnes of mixed waste every day which is reduced to about 40% of the total after segregation and then produces 12 MW of electricity.

- This technology is used efficiently in Singapore, Japan and many European countries with due precaution as they try to minimise the waste that needs to go to landfills.

- The purpose of a landfill is to isolate waste from its surrounding environment, preventing water contamination and contact with air. However, landfills are not built to decompose trash. As a result, there is contamination of the soil and water with toxins, causing leachate and the release of greenhouse gases.

Pyrolysis, gasification and plasma gasification

- Pyrolysis: produces combustible tar/biooil and chars

- Gasification: produces combustible gas, hydrogen, synthetic fuels

- Plasma gasification process: produces rich syngas including hydrogen and carbon monoxide usable for fuel cells or generating electricity

These are thermal technologies that are able to produce energy from waste and other fuels without direct combustion.

- In waste to energy plants, these technologies can deliver cleaner emissions but are considerably more expensive.

- It involves heating of solid waste at very high temperatures in an oxygen-controlled environment in a manner that the thermal reactions produce synthesis gas (or syngas).

- It has the advantage that it can be burned directly or transported through pipelines and/or tankers for use in electricity generation, refining, chemical and fertiliser industries.

- While syngas can be scrubbed and converted into a clean energy source, the technologies are expensive, compromising the commercial viability of plants based on conversion technologies.

- One such waste to energy plant based on pyrolysis-gasification technology was set up in Pune in 2012, but it has failed to deliver after repeated trials.

- It failed due to high cost of cleaning syngas and also because of a number of technical snags, including the fact that it had overestimated the calorific value of the waste and underestimated the moisture content.

- The company now produces RDF using 300 tonnes of dry municipal waste per day — less than half of what was intended in the design of the original plant.

Financial Viability

- The subsidies required to make waste to energy plants functional is a different challenge.

- These plants involve significant capital investment and the cost of energy produced is higher than from the grid. So, the subsidies can be provided only by the government.

- This is a beneficial investment as they contribute significantly in resource recovery and saving on the energy cost of transportation. Without them, there is diversion towards landfill which is more harmful abd non-productive.

- Hence, there should be a transparent method to determine the maximum subsidy feasible through competitive bidding.

- Also, PPP model can be implemented here where both government and private sector cooperate to keep the cities clean and sanitised.

Role of state

- The pollution control boards set up by central and state government were expected to provide technical assistance and keep a check on the emissions/environmental footprints of waste-to-energy plants.

- However, they did not keep pace with rapidly evolving technology in the field of pollution control and were not able to check routine defaulters.

- As a result, it was recognised that a more empowered body was needed that could enforce adherence to environmental regulations.

- This led to formation of National Green Tribunal in 2010 as an independent judicial body by an Act of Parliament of India.

- As a judicial body in charge of supervisory jurisdiction over all environmental matters, NGT has poked the pollution control authorities and catalysed action from State Pollution Control Boards/Municipalities, especially in waste management.

- NGT has been setting the rules and backing them up with legal compensation and enforcement behind its rulings. Now it needs support from CPCB to carry out scientific evaluations of the environmental impact of waste-to-energy plants.

Conclusion

All these plants are involved in process of generating electricity. However, it needs to be understood that electricity generation from waste is not the most efficient way of generating electricity. Rather, it is a way of resource recovery from municipal solid waste and should be considered as a by-product of waste management. Though it is not a solution to India’s energy problem, but if implemented at global emission standards, it could be a pathway to scientific and sustainable disposal of municipal solid waste, as there is scarcity of urban land in India and also helps in generating some much needed electricity.

Additionally, this can contribute in keeping environment clean and thereby contributing towards less greenhouse gas emissions as combustion technologies produce less GHG gases than landfills.

Connecting the dots:

- What is municipal waste management? Is it possible to generate energy out of waste? Examine.

MUST READ

Voting in a season of discontent

Don’t let messengers shoot themselves

The real meaning of independence for RBI

The new right

Permission To Prosecute

Tough times ahead for India in Afghanistan

Cyber war has gone public, and that’s bad

Violence against women hurts the economy

Rare diseases; orphan drugs

Baby steps to GST

India’s Pak policy must shift focus

MINDMAPS

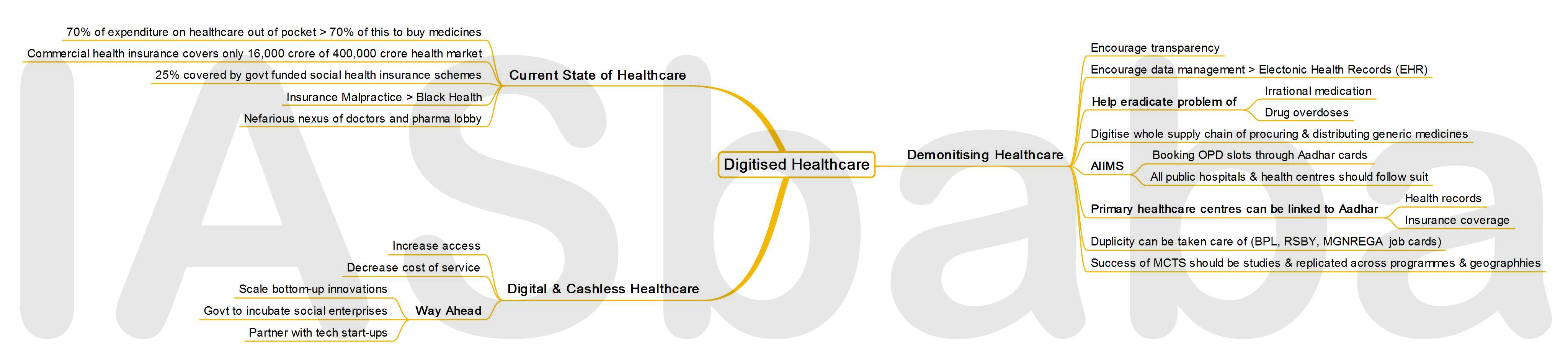

Digitised Healthcare