Baba’s Explainer, Science and Technology

Baba’s Explainer – Electric Vehicles and Battery Fires

Syllabus

- GS-3: Infrastructure and Economic Development

- GS-3: Science and Technology- developments and their applications and effects in everyday life.

Why in News: The Union Government has constituted an expert panel to probe the recent series of battery explosions in electric vehicles (EVs).

- Manufacturers like Okinawa and Pure EV have recalled some batches of electric scooters following fire incidents involving the vehicles.

- Recently, an 80-year-old man died at his home in Telangana’s Nizamabad district after the battery of an electric scooter exploded while being charged.

- EVs are vehicles that are either partially or fully powered on electric power.

- While some EVs used lead acid or nickel metal hydride batteries, the standard for modern battery electric vehicles is now considered to be lithium ion batteries (discussed in detail below)

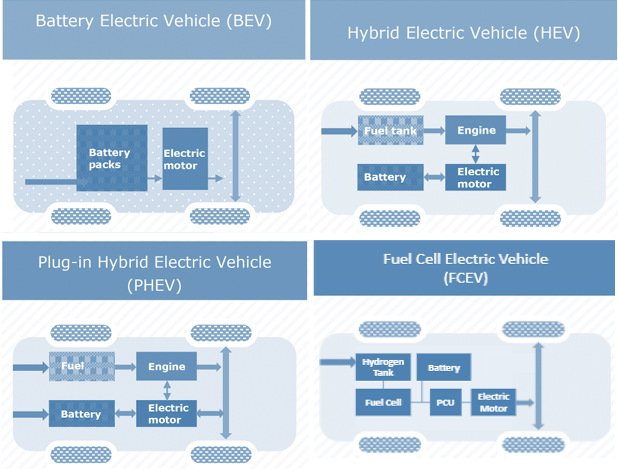

There are four types of electric vehicles available:

- Battery Electric Vehicle (BEV):Fully powered by electricity. These are more efficient compared to hybrid and plug-in hybrids.

- Hybrid Electric Vehicle:

- Hybrid Electric Vehicle (HEV): HEVs have both engine and electric motor. The engine gets energy from fuel, and the motor gets electricity from batteries. The transmission is rotated simultaneously by both engine and electric motor. This then drives the wheels.

- Plug-in Hybrid Electric Vehicle (PHEV): Uses both an internal combustion engine and a battery charged from an external socket (they have a plug). This means the vehicle’s battery can be charged with electricity rather than the engine. PHEVs are more efficient than HEVs but less efficient than BEVs.

- Fuel Cell Electric Vehicle (FCEV): FCEVs are also known as Zero-Emission Vehicles. They employ ‘fuel cell technology’ to generate the electricity required to run the vehicle. The chemical energy of the fuel is converted directly into electric energy. For example, a hydrogen FCEV.

- Climate Concerns: The growing concern over climate change has led to global efforts to electrify the transportation sector.

- Reducing Cost: In parallel, cost of Li-ion (Lithium-ion) battery technology has decreased by a staggering order of magnitude in the last decade.

- Government Push: Governments providing incentives to usher in the transition to electric mobility so as to emerge as leaders in the global market.

- Private Investment: There is a worldwide race emerging, with vehicle companies, battery manufacturers, and material suppliers vying with each other for market share. Thus, market forces are also pushing aggressively for transiting the mobility sector from petrol/diesel based to electric based.

- The convergence of above factors has resulted in a unique time in our history where we are at the cusp of a dramatic transition in the transportation sector, with electric vehicles poised to replace petrol vehicles.

- Energy Effeciency: EVs convert over 60% of the electrical energy from the grid to power at the wheels (petrol & diesel cars only convert 17%-21% of the energy stored in the fuel to the wheels)

- Low maintenance cost: EVs have very low maintenance costs because they don’t have as many moving parts as an internal combustion vehicle.

- Eco-friendly: Driving an electric vehicle can help you reduce your carbon footprint because there will be zero tailpipe emissions. Even when electricity production is taken into account, petrol or diesel vehicles emit almost 3 times more carbon dioxide than the average EV.

- One can reduce the environmental impact by choosing renewable energy options for recharging batteries

- To reduce the impact of charging electric vehicles, India is ambitious to achieve about 40 percent cumulative electric power installed capacity from non-fossil fuel-based energy resources by the year 2030.

- Tax and financial benefits: Registration fees and road tax on purchasing electric vehicles are lesser than petrol or diesel vehicles. There are multiple policies and incentives offered by the government depending on which state you are in.

- Easy to drive and quiet: Electric vehicles don’t have gears and are very convenient to drive. Electric vehicles are also quiet, as there is no engine under the hood. No engine means no noise.

- Reduced energy dependence: Electricity is a domestic energy source and the country’s dependency on oil imports will be reduced drastically.

- Electric vehicles are uneconomical

- Every new technology follows an economic path where the initial upfront price is higher. This reaches a maximum and then decreases when people adopt this technology commonly.

- Electric vehicles are the same, but the higher price points are quickly changing as the costs go down.

- Electric vehicles are more economical when we take fuel and maintenance costs.

- It takes too long to charge

- Cars spend over 90% of the time parked. One can plug in your car in this downtime at home/office to charge it.

- If one needs to charge quickly on the road, fast and rapid chargers are entering the Indian market. Some electric vehicles can charge from 20% – 80% in about half an hour on these chargers.

- Electric Vehicle batteries will only last a few years

- The fear of the short life span of batteries arises when we start comparing it with the batteries of our smartphones.

- The batteries used in electric vehicles are superior and designed to offer a long service life. Many manufacturers are providing warranties of 5 to 8 years on batteries.

- Electric vehicles have very low range

- The range of electric vehicles is enough for the typical daily mileage of the average Indian driver.

- As per the Bureau of Energy Efficiency, the average range of electric 2-wheelers currently available in the market is around 84 km per charge, which is enough for day-to-day travel within a city.

- The average range of electric cars available in the market is between 150-200 km per charge. This range, when considered with the continuously increasing charging infrastructure, makes commuting even inter-cities easier.

- Electric vehicles are slow and bad performance

- Electric vehicles perform better Than petrol or diesel vehicles because they are more efficient and have better acceleration.

- Electric vehicles are powered by an electric motor that generates torque instantly without any gears. As soon as you push down the accelerator, the electric vehicles will accelerate from stationary without lag.

- Electric vehicle charging stations are not enough

- There are already 934 charging stations in India with more and more providers, both public and private, entering the space.

- Measures have been taken by the government to ensure public charging infrastructure penetration further increases.

- The Ministry of Power (MoP) provides the following minimum requirements for the location of public charging stations: At least one charging station should be available in a grid of 3km x 3km; One charging station to be set up every 25km on both sides of highways/roads

- The Ministry of Housing and Urban Affairs (MoHUA) amended its Model Building Byelaws (MBBL) 2016 to include the provision of electric vehicle charging in buildings

- Electric Vehicles get damaged in waterlogged areas and are dangerous to charge in rains

- All electric vehicles come with compliance to an Ingress Protection (IP) as standard.

- Most of the electric vehicles have an IP67 rating or more; here 67 represents the protection against two elements – dust and water. To give you reference, anything past 67 is generally used for specialized equipment such as submarines.

- Electric Vehicles may eventually solve the tailpipe-emission problem, they don’t address all the damage done to the environment while making them

- As the EV gains momentum, battery production and research is powering ahead and sales are growing. That means material emissions will rise to over 60% by 2040 from 18% today.

- Decarbonizing the production phase of a car is harder than the use phase

- Currently battery units in EVs are heavy, increasing the total weight of the car, which in turn requires more energy to drive. To deal with this, carmakers are turning to aluminium for light-weight body designs, with EVs using 45% more of the Aluminium than traditional vehicles. Emissions from aluminium have started rising because it’s energy-intensive to mine and produce.

- Companies try to make batteries that can take cars further, they are using nickel, cobalt and manganese, which generate still more greenhouse gases.

- The high greenhouse gas emissions in the car manufacturing supply chain are “not even properly quantified by carmakers, because of poor disclosure of their suppliers’ emissions data

- Concerns of disposal of used & broken batteries are conveniently palmed off on poor, vulnerable countries – such as the Democratic Republic of Congo, which produces 60% of the world’s Cobalt – that lack the legislation to deal with them.

- Unavailability of Materials for Domestic Production: Battery is the single most important component of EVs. India does not have any known reserves of lithium and cobalt which are required for battery production.

- Dependence on other countries for the import of lithium-ion batteries is an obstacle in becoming completely self-reliant in the battery manufacturing sector.

- Weak Manufacturing base: It is estimated that by 2020-30 India’s cumulative demand for batteries would be approximately 900-1100 GWh. However, there is concern over the weak manufacturing base for batteries in India, leading to heavy reliance on imports to meet rising demand.

- India is among a handful of countries that support the global EV30@30 campaign, which aims for at least 30% new vehicle sales to be electric by 2030.

- FAME, or Faster Adoption and Manufacturing of (Hybrid and) Electric vehicles, is currently India’s flagship scheme for promoting electric mobility.

- Currently in its 2nd phase of implementation, FAME-II is being implemented for a period of 3 years, eff. 1st April 2019 with a budget allocation of 10,000 Cr.

- Government has also recently launched Production-Linked Incentive (PLI) scheme for Advanced Chemistry Cell (ACC) for the supplier side and PLI scheme for Auto and Automotive Components for manufacturers of electric vehicles.

The government offers different types of financial incentives to make electric vehicles more affordable for you. The key mechanisms for getting incentives are:

- Purchase Incentives: Direct discount provided to the user on the cost of the electric vehicle

- Coupons: Financial incentive where the amount is reimbursed later

- Interest Subventions: Discount offered on the interest rate while availing loan

- Road tax exemption: Road tax at the time of purchase is waived off

- Registration fee exemption: One-time registration fee applicable on new vehicle purchase is waived off

- Income tax benefit: Provided as a deduction on the tax amount payable by an individual to the government

- Scrapping incentives: Provided upon de-registering old Petrol and Diesel Vehicles

- Others: Incentives such as interest-free loans, top-up subsidies, special incentives on electric three-wheelers, etc. can also be availed.

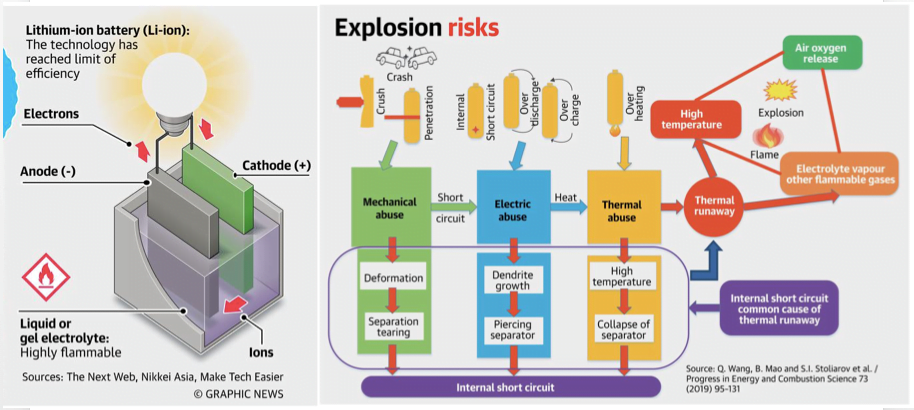

Every Li-ion battery consists of three active components:

- the anode, typically graphite;

- the cathode, typically based on a nickel, cobalt, and manganese-based oxide;

- an electrolyte, typically a salt of lithium in an inorganic solvent.

Battery manufacturing is a complex operation involving forming sheets of the anode and cathode and assembling them into a sandwich structure held apart by a thin separator.

- Separators, about 15 microns in thickness — about a fifth of the thickness of the human hair — perform the critical function of preventing the anode and cathode from shorting.

- Accidental shorting of the electrodes is a known cause of fires in Li-ion cells.

- Therefore, it is important that the various layers are assembled with high precision

- Safety features, such as thermal switches that turn off if the battery overheats, are added as the sandwich is packaged into a battery cell.

- Battery cells are assembled into modules and then further assembled into packs.

- There also involves sensors & sophisticated battery management system that interpret the data and change operations based on changes in the batteries state.

- The location of the battery should protect it from external penetration, ensure passenger safety while talking into consideration the overall weight distribution. Close interaction between vehicle manufacturers and battery manufacturers is essential.

What factors are leading to battery fires?

- Battery fires, like other fires, occur due to the convergence of three parts of the “fire triangle”: heat, oxygen, and fuel.

- If an adverse event occurs in the battery, the internal temperature can raise as the anode and cathode release their energy through the short.

- This, in turn, can lead to a series of reactions from the battery materials, especially the cathode, that release heat in an uncontrolled manner, along with oxygen.

- Such events also rupture the sealed battery further exposing the components to outside air and the second part of the fire triangle, namely, oxygen.

- The final component of the triangle is the liquid electrolyte, which is flammable and serves as a fuel. The combination leads to catastrophic failure of the battery resulting in smoke, heat, and fire, released instantaneously and explosively.

The trigger for an adverse event can be a result of

- Internal shorts (like a manufacturing defect that results in sharp objects penetrating the separator)

- External events (an accident leading to puncture of the cell and shorting of the electrodes)

- Overcharging the battery which leads to heat releasing reactions on the cathode (by a faulty battery management system that does not shut down charging despite the battery achieving its designed charge state)

- Bad thermal design at the module and pack level (by not allowing the battery internal heat to be released).

- Preventing fires requires breaking the fire triangle.

- Battery cathodes are a leading cause of the heat release. Some cathodes, such as ones with lower nickel content or moving to iron phosphate, can increase safety.

- Tightly controlled manufacturing will prevent accidental shorts in the cells, eliminating a leading cause of fires.

- Many companies now add a ceramic layer on the separator to mechanically prevent shorts

- Protecting the cell with robust thermal management is critical, especially in India where ambient temperatures are high.

- Companies are developing internal “switches” that turn off parts of the battery that undergo thermal events to stop them at their inception.

- Research is now underway to replace the flammable liquid electrolyte with a solid electrolyte to eliminate one part of the fire triangle.

- Debates are mounting on whether battery swapping would be a better solution for electric scooter in India.

- One of the key elements of EV, charging is in complete control of the swapping company and the customer never has to charge the battery.

- The other advantage of swapping is that there is always an extra pool of batteries giving ample time to charge the batteries.

- Engineering safety requires commitment from all parts of the battery supply chain and tight integration between vehicle companies and battery companies.

- Further, regulators play an important role, providing the testing and certification needed to ensure battery safety.

- Safety is a must and is an important consideration that battery and vehicle manufacturers can design for at multiple levels from the choice of battery material to designs at the cell, pack, and vehicle level.

- To ensure that carbon footprint is further reduces, the best path forward is to start with better disclosure on life-cycle emissions of EVs.

- There is need to make better EV batteries, so as to get more energy into a smaller, lighter batteries.

- There is need for realistic solutions like battery recycling, prioritizing types that use less carbon-intensive materials, or emission caps on the battery and electric vehicle manufacturing process.

Statistics of auto market in Norway

- In 2020, the market share of battery electric vehicles (BEVs) rose to 54%, up from 42% in 2019.

- Only a decade ago, BEVs made up just 1 per cent of the overall market.

- If hybrid vehicles are included, the share of electric vehicles sold in 2020 is 83 per cent.

- Petrol and diesel cars sold, which commanded a 71 per cent market share in 2015, are now at 17 per cent.

- There are 2.8m vehicles on Norway’s roads and more than 260,000 are fully electric, nearly 9% of the total car stock.

Norway became an electric vehicles power due to the following factors

- Futuristic Shift: Norway, which is the biggest producer of crude oil in Western Europe, has in the recent past made a shift from fossil fuels to renewable energy.

- Early Start in 1990s itself: A country roughly the size of Maharashtra in terms of area, it began the electric push in the 1990s in an effort to cut pollution, congestion, and noise in urban centres.

- Ambitious Target: In 2017, Norway’s parliament set a non-binding goal to ensure that all cars sold should be zero emissions by 2025. The UK and Germany plan to do this by 2030, and France by 2040. In India, the government has set a target of 30 per cent vehicles becoming EV by 2030

- Reduced taxes: Norway has some of the highest taxes in the world on what it regards as luxury goods, which includes cars. So reduced taxes on electric vehicles, with numerous incentives, is bound to entice car buyers.

- Incentives: The government lets electric cars run on bus lanes, while toll roads are free for them. Also, Parking lots offer a free charge for electric vehicles.

- Charging Infrastructure: New charging stations are continuously being built on the nation’s highways — a mix of regular charging stations and fast-chargers. At the moment, Norway has 10,000 publicly available charging points.

- Policy Tweaks: The country’s policies have also encouraged carmakers to use Norway as a testing ground. As per the CNNreport, Volkswagen’s luxury brand Audi was the market leader in 2020, selling 9,227 units of its e-tron model, followed by Tesla’s Model 3, which sold 7,77o units.

- Blessed with Natural resource: While Norway is still one of the world’s big oil producers, it gets more than 90% of its power from hydroelectric sources. This goes some way to explain why the introduction of electric vehicles has been such a winner: as long as the rivers and waterfalls don’t run dry, this is an infinite source of power that can also be applied to vehicles.

Mains Practice Question – Discuss how Electric Vehicles (EVs) offer a promising future to India’s transport sector and the obstacles in realising its full potential.

Note: Write answers to this question in the comment section