Economics, Environment & Ecology

Syllabus

- GS-3: Economy & energy; Environmental Conservation

- GS-2: Government policies and interventions for development in various sectors and issues arising out of their design and implementation.

Why in News: The Union Cabinet recently advanced by five years its target for achieving 20% ethanol blending in petrol.

- The amended National Biofuel Policy-2018 has now set the new target for 2025-26 instead of 2030, apart from allowing more feedstock for production of biofuels and export of biofuels in specific cases.

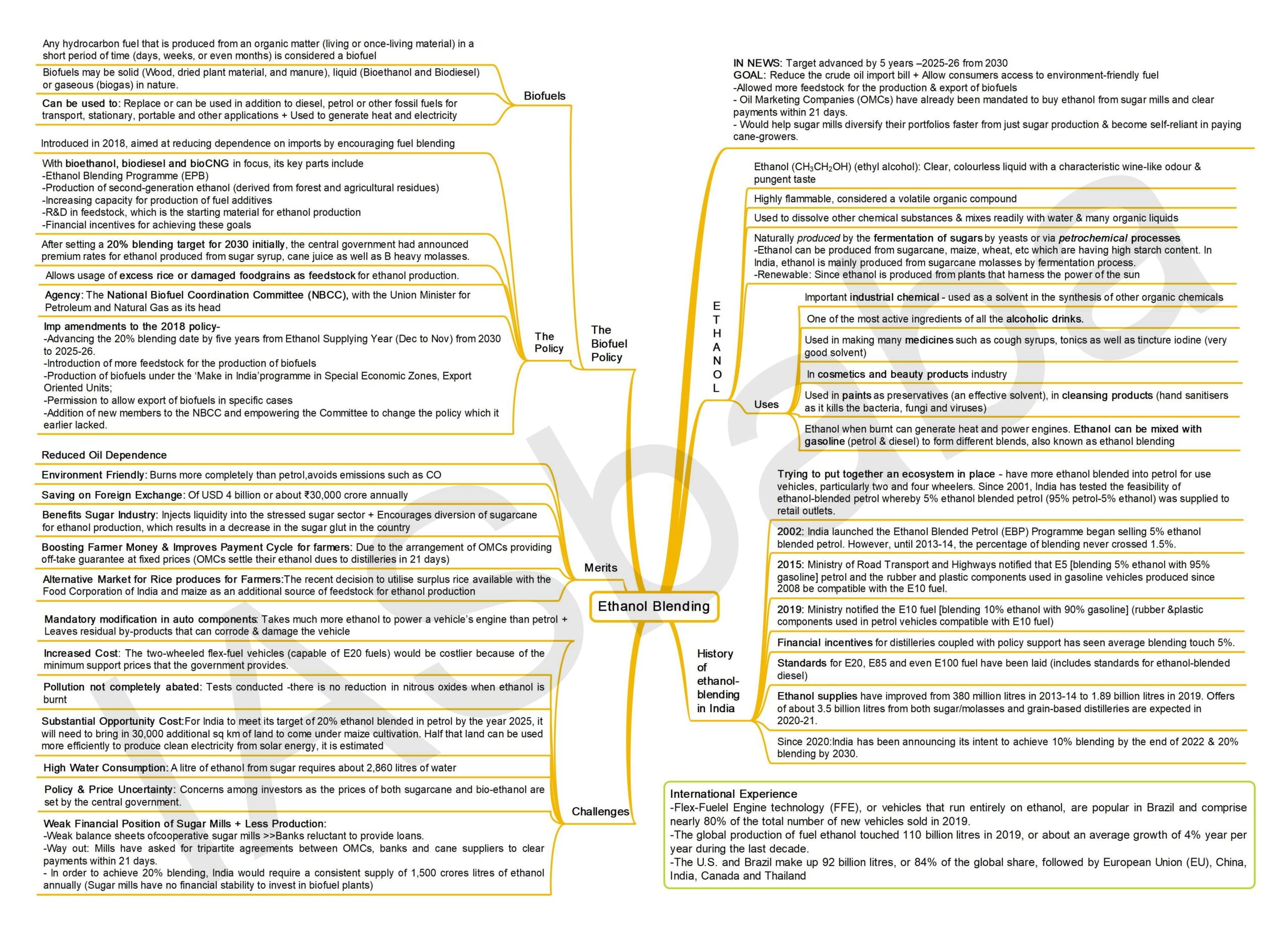

What is ethanol and what are its characteristics?

- Ethanol (CH3CH2OH) also known as ethyl alcohol, is a clear, colorless liquid with a characteristic wine-like odour and pungent taste.

- It is highly flammable and is considered a volatile organic compound

- Ethanol is used to dissolve other chemical substances and mixes readily with water and many organic liquids.

- It is one of the principal biofuels naturally produced by the fermentation of sugars by yeasts or via petrochemical processes

- Ethanol can be produced from sugarcane, maize, wheat, etc which are having high starch content. In India, ethanol is mainly produced from sugarcane molasses by fermentation process.

- Since ethanol is produced from plants that harness the power of the sun, ethanol is also considered as renewable fuel.

What are the uses of ethanol?

- Ethanol is a very important industrial chemical which is used as a solvent in the synthesis of other organic chemicals.

- Ethanol is one of the most active ingredients of all the alcoholic drinks.

- It is also used in making many medicines such as cough syrups, tonics as well as tincture iodine as it is a very good solvent

- In cosmetics and beauty products industry, it is a common ingredient when it comes lotions as preservatives for helping the skin.

- It is used in paints as preservatives because it is an effective solvent.

- It is also used in cleansing products like hand sanitisers as it kills the bacteria, fungi and viruses that could be harmful to us.

- Ethanol when burnt can generate heat and power engines. Ethanol can be mixed with gasoline (petrol & diesel) to form different blends, also known as ethanol blending

What is the history of ethanol-blending in India?

- Since two decades, India has been moving towards putting in place an ecosystem to have more ethanol blended into petrol for use vehicles, particularly two and four wheelers.

- Government records suggest about 75% of India’s 220 million vehicles are two wheelers and 12% four wheelers.

- Since 2001, India has tested the feasibility of ethanol-blended petrol whereby 5% ethanol blended petrol (95% petrol-5% ethanol) was supplied to retail outlets.

- In 2002, India launched the Ethanol Blended Petrol (EBP) Programme and began selling 5% ethanol blended petrol in nine States and four Union Territories that was extended to twenty States and four UTs in 2006.

- Until 2013-14, however, the percentage of blending never crossed 1.5%.

- In 2015, the Ministry of Road Transport and Highways notified that E5 [blending 5% ethanol with 95% gasoline] petrol and the rubber and plastic components used in gasoline vehicles produced since 2008 be compatible with the E10 fuel.

- In 2019, the Ministry notified the E10 fuel [blending 10% ethanol with 90% gasoline]. The rubber and plastic components used in petrol vehicles are currently compatible with E10 fuel.

- Financial incentives for distilleries coupled with policy support has seen average blending touch 5%.

- Standards for E20, E85 and even E100 fuel have already been laid. This includes standards for ethanol blended diesel.

- Ethanol supplies have improved from 380 million litres in 2013-14 to 1.89 billion litres in 2019. Offers of about 3.5 billion litres from both sugar/molasses and grain-based distilleries are expected in 2020-21.

- In 2019, in a first for the Republic Day parade, the Indian Air Force flew aircraft in a Vic formation, with the lead plane using a mix of traditional fuel and biofuel, symbolising the government’s determination to seek alternative sources of fuel.

- Since 2020, India has been announcing its intent to achieve 10% blending by the end of 2022 and 20% blending by 2030. The Centre has also targeted 5% blending of biodiesel with diesel by 2030.

What is the biofuel policy?

- Biofuels are any hydrocarbon fuel that is produced from an organic matter (living or once living material) in a short period of time (days, weeks, or even months) is considered a biofuel.

- Biofuels may be solid, liquid or gaseous in nature.

- Solid: Wood, dried plant material, and manure

- Liquid: Bioethanol and Biodiesel

- Gaseous: Biogas

- These can be used to replace or can be used in addition to diesel, petrol or other fossil fuels for transport, stationary, portable and other applications. Also, they can be used to generate heat and electricity.

- There are four categories of biofuels

- First Generation: made from food sources such as sugar, starch, vegetable oil, or animal fats using conventional technology. It entails food vs fuel debate. Ex: Bioalcohols, Biodiesel,

- Second Generation: produced from non-food crops or portions of food crops that are not edible and considered as wastes, e.g. stems, husks, wood chips, and fruit skins and peeling. Ex: cellulose ethanol, biodiesel.

- Third Generation: produced from micro-organisms like algae. Example- Butanol

- Fourth Generation Biofuels: Crops are genetically engineered to take in high amounts of carbon are grown and harvested as biomass. The crops are then converted into fuel using second generation techniques.

- Introduced in 2018, the National Biofuel Policy is aimed at reducing dependence on imports by encouraging fuel blending.

- With bioethanol, biodiesel and bioCNG in focus, its key parts include

- Ethanol Blending Programme (EPB)

- production of second generation ethanol (derived from forest and agricultural residues)

- increasing capacity for production of fuel additives

- R&D in feedstock, which is the starting material for ethanol production

- financial incentives for achieving these goals.

- After setting a 20% blending target for 2030 initially, the central government had announced premium rates for ethanol produced from sugar syrup, cane juice as well as B heavy molasses.

- Molasses is the sticky liquid formed during sugar production from cane juice, and depending on the percentage of sugar left, it is categorized as B heavy and C.

- Molasses is the feedstock used by sugar mills to produce ethanol.

- The policy also allows usage of excess rice or damaged foodgrains as feedstock for ethanol production.

- The National Biofuel Coordination Committee (NBCC), with the Union Minister for Petroleum and Natural Gas as its head, is the agency to coordinate this blending programme.

- The 2018 policy was amended recently to introduce several changes. The most important amendment has been

- Advancing the 20% blending date by five years from Ethanol Supplying Year (Dec to Nov) from 2030 to 2025-26.

- Introduction of more feedstock for production of biofuels

- Production of biofuels under the ‘Make in India’ programme in Special Economic Zones, Export Oriented Units;

- Permission to allow export of biofuels in specific cases

- Addition of new members to the NBCC and empowering the Committee to change the policy which it earlier lacked.

What does advancing the blending target mean?

- Given the skyrocketing fuel prices, the blending programme has a dual purpose –

- to reduce the crude oil import bill

- to allow consumers access to environment friendly fuel.

- For this, Oil Marketing Companies (OMCs) have already been mandated to buy ethanol from sugar mills and clear payments within 21 days.

- The decision would help sugar mills diversify their portfolios faster from just sugar production and become self-reliant in paying cane-growers.

What are the merits of Ethanol Blending?

- Reduced Oil Dependence: Ethanol can be sourced from sugarcane, molasses, maize, which given India’s agricultural base, can substantially reduce India’s dependence on petroleum.

- Environment Friendly: Because ethanol burns more completely than petrol, it avoids emissions such as carbon monoxide.

- Saving on Foreign Exchange: India’s net import of petroleum was 185 million tonnes in 2020-21 at a cost of USD 55 billion. Most of the petroleum products are used in transportation and therefore, the E20 programme can save the country USD 4 billion or about ₹30,000 crore annually

- Benefits Sugar Industry: Ethanol Blending programme injects liquidity into the stressed sugar sector. This programme also encourages diversion of sugarcane for ethanol production, which results in a decrease in the sugar glut in the country.

- Once 20 per cent blending is achieved, 60 lakh tonnes of sugar would have to be diverted annually to produce the fuel additive.

- Boosting Farmer Money: In India, ethanol is mainly produced from sugarcane molasses by fermentation process. Usage of sugarcane for ethanol production can help provide additional venue for farmers to increase their income.

- Improves Payment Cycle for farmers: The arrangement of OMCs providing off-take guarantee at fixed prices also improves the health of the payment cycle to farmers since OMCs settle their ethanol dues to distilleries in 21 days instead of the months that the farmers had to wait for their payment from sugar mills.

- Alternative Market for Rice produce: The recent decision to utilise surplus rice available with the Food Corporation of India and maize as an additional source of feedstock for ethanol production, starting this year, means farmers will now have an alternative market for their produce.

What are the challenges with Ethanol Blending?

- Mandatory modification in auto components: It takes much more ethanol to power a vehicle’s engine than petrol. It also leaves residual by-products that can corrode and damage the vehicle which is why, while vehicles can be run on ethanol, they need to be tuned accordingly so that they don’t compromise on efficiency and usability.

- Increased Cost: The two-wheeled flex fuel vehicles (capable of E20 fuels) would be costlier by ₹5,000 to ₹12,000 compared to regular petrol vehicles. Also, the prices of ethanol produced in India are higher compared to U.S. and Brazil, because of the minimum support prices that the government provides.

- Pollution not completely abated: Tests conducted in India have shown that there is no reduction in nitrous oxides when ethanol is burnt, one of the major environmental pollutants.

- Substantial Opportunity Cost: For India to meet its target of 20% ethanol blended in petrol by the year 2025, it will need to bring in 30,000 additional sq km of land to come under maize cultivation. Half that land can be used more efficiently to produce clean electricity from solar energy, it is estimated.

- Weak Financial Position of Sugar Mills: Many cooperative sugar mills have complained about a fund crunch. Banks, they claim, are reluctant to finance sugar mills given their weak balance-sheets. As a way out, mills have asked for tripartite agreements between OMCs, banks and cane suppliers to clear payments within 21 days. However, most banks have expressed their apprehensions.

- High Water Consumption: For India, sugarcane is the cheapest source of ethanol. A litre of ethanol from sugar requires about 2,860 litres of water.

- Less Production: Sugar mills, which are the key domestic suppliers of bio-ethanol to OMCs, were able to supply only 57.6% of the total demand. Sugar mills do not have the financial stability to invest in biofuel plants.

- In order to achieve 20% blending, India would require a consistent supply of 1,500 crores litres of ethanol annually.

- Policy Uncertainty: There are also concerns among investors on the uncertainty on the price of bioethanol in the future as the prices of both sugarcane and bio-ethanol are set by the central government.

What is the international experience?

- Flex Fuel Engine technology (FFE), or vehicles that run entirely on ethanol, are popular in Brazil and comprise nearly 80% of the total number of new vehicles sold in 2019.

- The global production of fuel ethanol touched 110 billion litres in 2019, or about an average growth of 4% year per year during the last decade.

- The U.S. and Brazil make up 92 billion litres, or 84% of the global share, followed by European Union (EU), China, India, Canada and Thailand.

Mains Practice Question – Ethanol blending is not without its problems. Elaborating on this statement, discuss the merits of accelerating the ethanol blending programme of India.

Note: Write answers to this question in the comment section.

Mind Map

DOWNLOAD MIND MAP – CLICK HERE