Economics

Context:

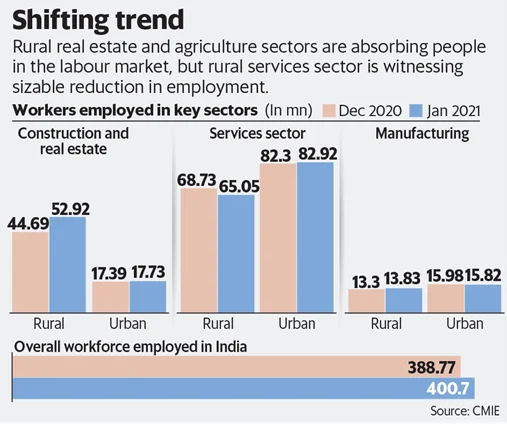

- There is growing evidence to suggest that the most conspicuous trend in the manufacturing sector in India has been a shift of manufacturing activity and employment from bigger cities to smaller towns and rural areas.

- This has often been interpreted as a mixed bag, as it could transform the rural economy, but presents a set of constraints, which could hamper higher growth.

- However, the compulsions of global competition often extend beyond the considerations of low-wage production and depend on the virtues of ‘conducive ecosystems’ for firms to grow.

Current rural scenario:

- Urban-rural manufacturing shift:

- Work Bank report (Ghani, Ejaz et al (2012) “Is India’s Manufacturing Sector Moving Away from Cities? Policy Research Working Paper, World Bank”).

- Manufacturing is moving towards rural areas, while informal sector is moving from rural to urban locations.

- Significant contributor to manufacturing Output:

- Annual Survey of Industries for 2019-20 – 42% of factories are in rural areas, 62% of fixed capital is in the rural side.

- Rural factories contributed to exactly half of the total manufacturing sector.

- Employment:

- In terms of employment, it accounted for 44%, but had only a 41% share in the total wages of the sector.

- Production cost differentials – Wages, property, and land costs are all lower than in most metropolitan areas.

- Cheap labour: Big firms deliberately shift production from cities to take advantage of the availability of less skilled, less unionised and less costly rural labour.

- Factory floorspace supply constraints – When locations get more urbanised and congested, the greater these space constraints are.

- Capital restructuring – there is a tendency for growing capital accumulation and centralisation by large multi-plant corporations.

Significance of shift:

- Helped maintain the importance of manufacturing as a source of livelihood diversification in rural India.

- This trend helped to make up for the loss of employment in some traditional rural industries.

- In the aftermath of trade liberalisation, import competition intensified for many Indian manufacturers, forcing them to look for cheaper methods and locations of production.

- One way to cut costs was to move some operations from cities to smaller towns, where labour costs are cheaper.

- an economic base for the transition out of agriculture.

Challenges:

- Higher cost of capital for firms operating on the rural side, despite benefits of lower costs via lower rents

- The rural segment accounted for only 35% of the total rent paid, while it had 60% of the total interest payments.

- The benefits reaped from one source seem to be offset by the increased costs on the other front.

- Skills shortage in rural areas

- Manufacturing needs higher skilled workers to compete in the highly technological global ‘new economy’.

- Manufacturers who depend only on low-wage workers simply cannot sustain their competitive edge

- Manufacturers who need higher skilled labour find that rural areas cannot supply it in adequate quantities.

Suggestions:

- Institutional arrangements:

- The Ministry of Micro, Small and Medium Enterprises encompasses many such organisations – KVIC, National Small Industries Corporation Limited (NSIC), Coir Board, Council for Advancement of, NABARD, SIDBI

- Khadi and Village Industries Commission (KVIC): SFURTI – Scheme of Fund for Regeneration of Traditional Industries, PMEGP – Prime Minister’s Employment Generation Programme

- National Small Industries Corporation Limited: Export credit insurance Rural Industrialization, Raw Material assistance, Providing Infomediary Services, etc.

- Integrated infrastructural development:

- Nayak Committee (1992) recommendations – raising project outlay from Rs.30 lakh to Rs.50 lakh in the single window scheme, timely supply of credit, etc.

- Government programs:

- Cluster Development Programme: For holistic development of selected MSEs clusters through value chain and supply chain management on cooperative basis.

- Rural Industry and Entrepreneurship (ASPIRE) – implementing incubation and commercialisation of Business Ideas Programme through technical/research institutes

- Credit Linked Capital Subsidy Scheme (CLCSS) –

Technology upgradation of small-scale industries, including khadi, village and coir industrial units, by providing 15 percent upfront capital subsidy (limited to a maximum of Rs 15 lakh). - Prime Minister’s Employment Generation Programme (PMEGP) – implemented by KVIC, a total of 5.45 lakh micro enterprises have been assisted with a margin money subsidy of Rs 12,074.04 crore, providing employment opportunities to an estimated 45.22 lakh persons since 2019.

- Provision of more education and skilling for rural workers.

- To establish rural areas’ comparative advantage of low wages, higher reliability and productivity

- hasten the process of the movement out of agriculture to higher-earning livelihoods.

- Augmentation of Sources of Demand and Supply Opportunities for Large-Scale Industries – utilization of traditional methods and materials in small-scale industries will make provision of enhancement opportunities for rural individuals.

Way forward:

- Need for clear solutions to the problems of rural manufacturing so that rural economy can jump-start a revival.

- Given the size of the Indian economy and the need for balanced regional development, the dispersal of manufacturing activities is a welcome sign.

Source: The Hindu